Sound absorption vs. soundproofing

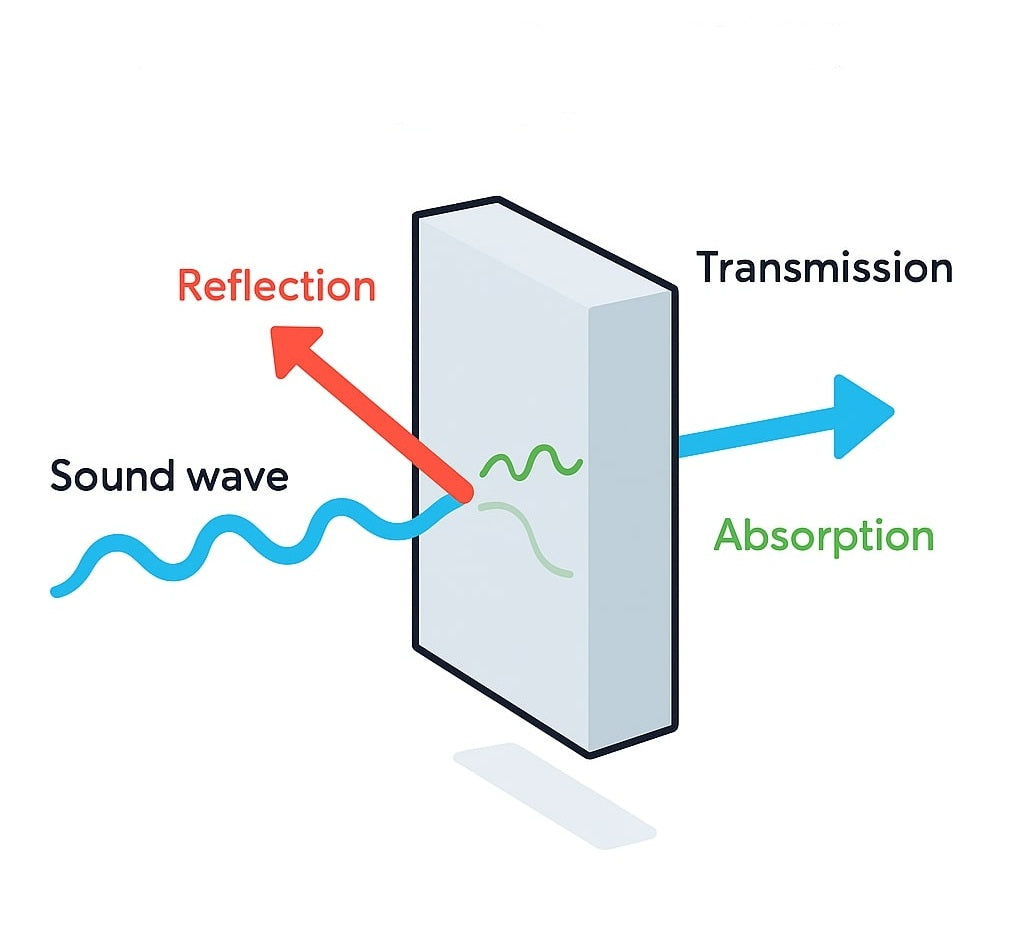

Sound absorption improves the sound quality inside a room, while soundproofing blocks sound from entering or leaving it. Although the terms are often used interchangeably, they describe very different acoustic mechanisms and lead to very different design outcomes.

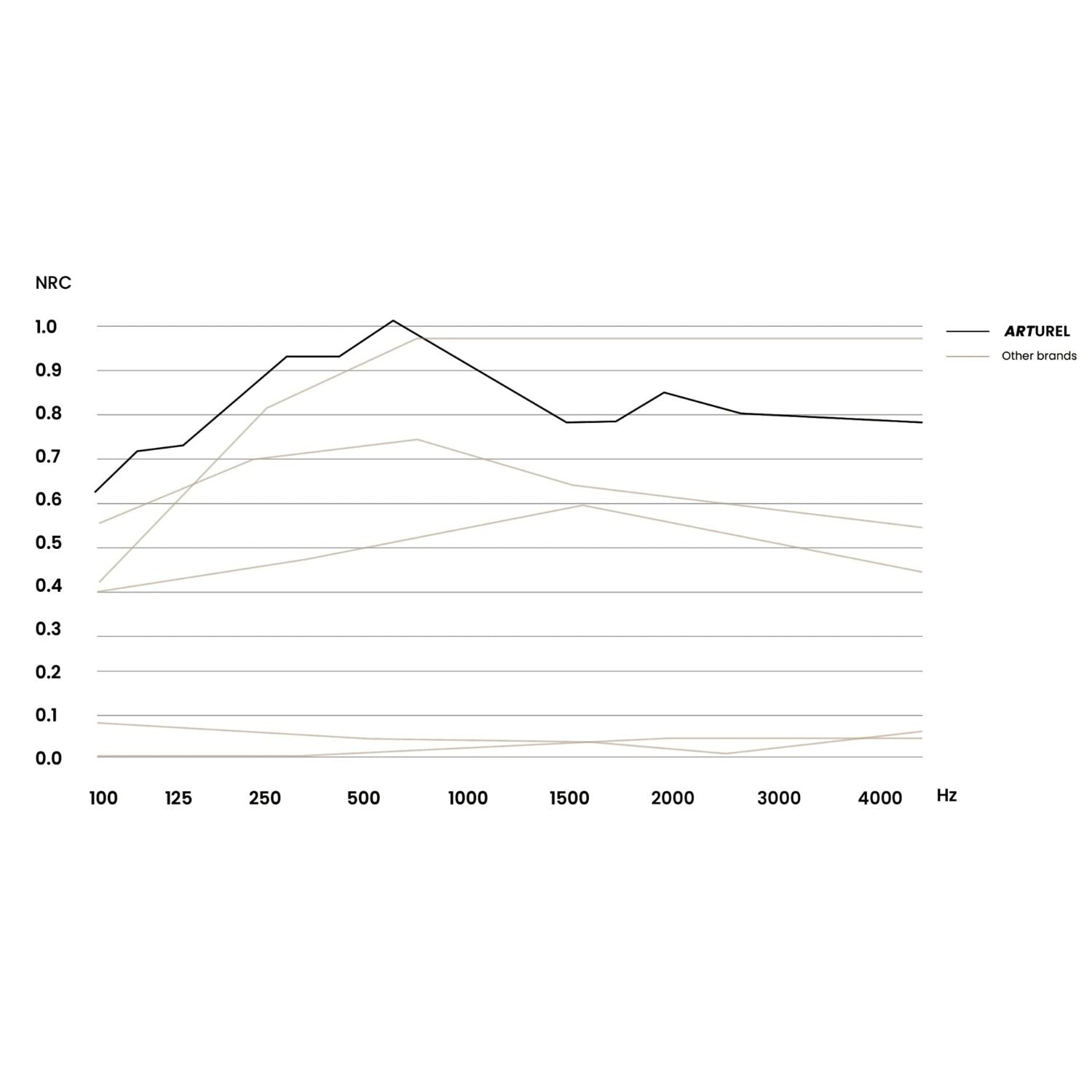

Absorption is about managing what happens to sound energy after it is generated in a room. Acoustic panels absorb a portion of the sound waves that strike them, preventing repeated reflections and reducing reverberation time. The result is a calmer, clearer acoustic environment where speech is easier to understand and background noise feels less fatiguing.

Soundproofing, on the other hand, addresses transmission by reventing sound from passing through walls, floors, or ceilings. This requires mass, airtight construction, and often multiple layers of dense materials. A lightweight wall with decorative acoustic panels may reduce echo inside the room, but it will not stop traffic noise or a loud neighbor from being heard. To achieve that, engineers rely on barrier design, heavy partitions, and resilient connections that break vibration paths.

Scientific research underlines this distinction. Studies on acoustic metamaterial sandwich panels show how advanced multi-layered systems can achieve high sound transmission loss by combining resonant elements with traditional mass-barrier approaches. These structures are optimized to block specific frequency ranges, demonstrating how soundproofing is an engineering problem of controlling vibration and transmission paths, not surface absorption.

For end-users, the key is setting the right expectations. Acoustic panels are not ‘miracle modules’ that make noise vanish – as we also explain in our article on do soundproofing panels work. Instead, they transform the experience of sound within a room by reducing harsh reflections, making speech more intelligible, and lowering the mental load of constant background noise. In many cases, panels form part of a larger strategy:

Absorption for comfort, soundproofing for isolation.

Our panels are designed for absorption, not soundproofing in its technical sense, and we emphasize the wellbeing benefits that come from better room acoustics.